To start the turbine, a blower is connected to the compressor inlet. Fuel is injected into the combustion chamber, and is ignited. The combustion products expand through the turbine, and the power generated is transmitted by the turbine shaft to the compressor. The shaft speed increases, and when the turbine is generating enough power, the external blower is switched off, and the rig continues to run by itself.

My original blower consisted of four, two stage 750W motor/impeller assemblies taken from standard Electrolux domestic vacuum cleaners. These are mounted in a box, like a speaker cabinet. Each one is capable of generating a large static pressure.

Connecting four in parallel gives the same pressure, at four times the air massflow. This is capable of driving the turbo to about 20,000 rpm with no combustion if the oil is warm (~20C). The blower speed can be controlled using a thyristor phase angle power controller.

Recently I discovered that I can start the rig with very much less power than I originally thought, and the starter blower is now a single 36V d.c. industrial vacuum cleaner module. This enables me to start and run the rig without any mains utility supply.

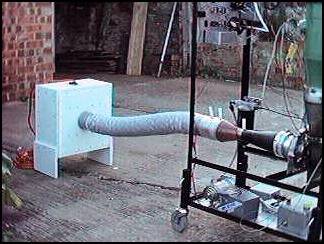

In the image below the starter blower, in the blue can, is connected to the rig via a flexible duct. The blower is standing on the battery carrier, which contains four 10Ahr lead-acid batteries.

I have also looked at compressed air as another stored energy starter system. The compressor housing is fitted with some air nozzles. Compressed air can be supplied to these nozzles to spin the turbine shaft up to self-sustain speed from from a small (1.5 litre) 200 bar (3000psi) air bottle. This is quite convenient, because it would allow starting to take place with the inlet silencer in place - fitting a blower requires the silencer to be removed until self-sustain has been acheived.

This has not been fully tested yet, because of the success of the d.c. blower starter. The compressed air starter is extremely noisy, another reason to stay with the d.c. blower !